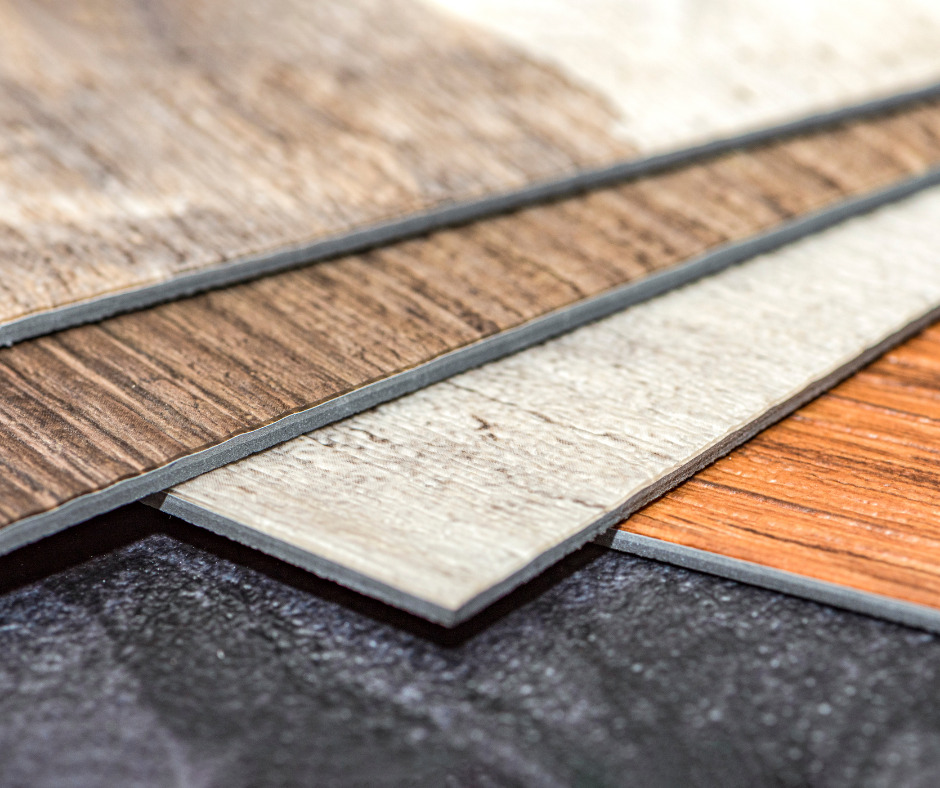

Wood-like tile flooring is a practical and cost-efficient alternative to traditional hardwood flooring. It provides the warmth and beauty of natural wood while being less prone to scratches, dents, and water damage. This guide will explore the wonders of wood tile flooring, its pros and cons, popular styles and patterns, and maintenance tips.

So, if you are considering wood tile flooring for your home or office, keep reading to discover everything you need to know.

Wood tile has a rich history that stretches back many centuries. The desire to replicate wood's natural warmth and beauty has always been present, even in ancient civilizations. While their techniques were less advanced than today's, they laid the foundation for developing wood tiles.

In ancient times, civilizations such as the Egyptians and Romans showcased their ingenuity through intricate mosaic designs. These designs often incorporated patterns that imitated the look of wood using materials like stones, glass, or even colored clay. These early attempts at reproducing wood-like patterns set the stage for the future of wood tile flooring.

Over time, the concept of wood tile floors continued to evolve. Advancements in technology and manufacturing techniques allowed for the creation of more realistic wood-like tiles. Printing techniques became more sophisticated, enabling tile manufacturers to replicate various wood species' textures, colors, and grain patterns.

The 20th century marked a significant turning point for wood tile flooring. Technological advancements and improvements in production methods greatly impacted the industry, creating more advanced and realistic wood tile options.

One of the most significant breakthroughs was the introduction of porcelain and ceramic tiles. Porcelain tiles, in particular, revolutionized the wood tile flooring industry. Porcelain is known for its exceptional durability, moisture resistance, and low maintenance requirements.

This made it ideal for areas with high moisture levels, such as bathrooms and kitchens. Ceramic tiles also played an important role, with their versatility in design options and ability to mimic the look of different wood species.

The advancements in printing technology allowed for the creation of wood tile flooring that not only replicated the appearance of wood but also captured the natural variations and characteristics of real wood. Manufacturers could incorporate intricate details such as knots, grain patterns, and shading, making wood-like tiles virtually indistinguishable from wood.

Furthermore, the advancements in production techniques made wood tile flooring more readily available and cost-effective than traditional hardwood flooring. Homeowners could now enjoy the timeless beauty of wood without the associated maintenance and durability concerns.

Wood tile flooring is a popular option for many homeowners thanks to its natural beauty, durability, and sustainability. The production journey of wood tile flooring is complex, involving many stages before reaching homeowners' floors. Below is an overview of the wood's journey, from sourcing to manufacturing the final product.

The production of wood tile flooring begins with sourcing high-quality wood from sustainable forests. Lumber harvested from responsible forestry practices ensures the future of our planet's forests, the protection of wildlife habitats, and the preservation of biodiversity.

Once harvested, the logs are transported to a processing facility, where they undergo debarking, sawing, and grading. The logs are debarked to remove the bark and any dirt that may have accumulated while transporting.

The logs are then sawed into lumber to create planks of wood that will be further processed into wood tile flooring. The lumber is graded by the quality of the wood and assigned a specific grade based on the appearance and strength of the wood.

The manufacturing process of wood tile flooring begins with the selection of raw materials, such as porcelain or ceramic, which will create the base and finish of the wood tile product. These materials are shaped and prepared into tiles that mimic the look, texture, grain, and variations of natural wood planks.

The printing technology allows the tile makers to create photo-realistic images of desired wood species from the surface imperfections found in natural wood grains, knots, and saw marks, resulting in a realistic representation of natural wood.

Once the tiles have been printed, they are fired at extreme temperatures to ensure they are durable and last for years. The firing temperature results in the final look of the tile, including color retention, texture, and finish. The high fire temperature makes it easy to clean and maintain, ideal for high-traffic areas.

After the final quality check, the tiles are packed and shipped to retailers, wholesalers, and homeowners.

Wood tile flooring is a wonderful alternative to traditional hardwood flooring, offering many benefits that make it a popular choice amongst homeowners. Below are some of the key benefits of wood tile flooring:

One of the most significant benefits of wood tile flooring is its exceptional durability and long-lasting nature. Unlike hardwood flooring, which can be susceptible to scratches, dents, and wear and tear, wood tile flooring is highly resistant to these damages. It can also handle heavy foot traffic and endure various environmental factors, including moisture and temperature changes, without losing its integrity.

Another advantage of wood tile flooring is its low maintenance and cleaning requirements. The flooring's hard surface is easy to clean with a damp mop or cloth, and dirt, dust, and debris can be easily removed without leaving scratches. Stains are also less likely to leave permanent marks on wood tile flooring, making it ideal for spaces with high traffic or prone to spills, such as kitchens and bathrooms.

Wood tile flooring comes in a wide variety of design options, offering versatility in style and size. It can accommodate various design preferences, from modern to traditional, rustic to contemporary, and everything in between. The flooring can also imitate different wood species, enabling homeowners to achieve the desired look without the maintenance or cost of real hardwood.

The production process of wood tile flooring is more eco-friendly and sustainable than hardwood flooring. Unlike traditional hardwood flooring, which requires cutting down many trees, wood tile flooring is made from recycled materials, including porcelain and ceramic. These materials are highly durable and can last for decades, reducing the overall waste produced by the flooring industry.

Moreover, producing wood tile flooring requires fewer resources and has a smaller environmental impact than traditional hardwood flooring. From the production of raw materials to transportation and installation, wood tile flooring reduces energy consumption and greenhouse gas emissions.

The wonders of wood tile flooring are unveiled through its durability, easy maintenance, versatile design options, and eco-friendliness. It is a flooring option that offers the best of both worlds – the timeless beauty of wood and the practicality of a modern manufacturing process.

Whether you are looking to replace your current flooring or enhance the aesthetics of your space, wood tile flooring is a remarkable choice that brings style, durability, and sustainability to any home.